Marine

.png)

1. S-Lay Method

2. J-Lay Method

3. Reel-Lay Method

Figure 4 Reel-Lay Configuration (left: S-Lay, right J-Lay) [2][6]

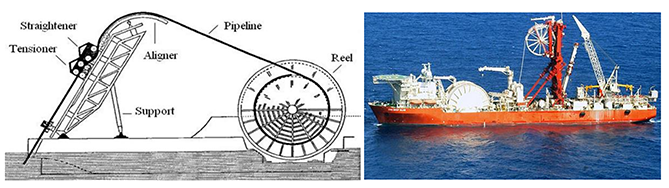

In this method, the amount of pipe can be laid is limited to the drum capacity. So, the vessel need to back to spool base to take more drum to continue the laying. However, because of that problem, for short distance pipe laying, this method is very efficient. The lay rate of this vessel is up to 20 km/day with vessel cost is $200,000 /day. This method is very cheap. However, the pipeline diameter is limited to 18 inch. The reason it cannot lay higher diameter of pipeline is because with higher pipeline diameter, the wall thickness usually will increase and this result in the plastic deformation. The plastic deformation of high diameter pipeline will surpass the allowable threshold (when reeled to drum) [5].

4. Towed System

·Bottom Tow

·Off Bottom Tow

·Mid-depth Tow

·Surface Tow

Figure 6 Surface Tow (left) and mid-depth tow (right) [2]

This four method is widely used around the world. The method selection is depend on many consideration and circumstances. Table 1 show the summary of pipe laying system comp.

.png)

Pipe-laying Method in Offshore / Subsea Construction

There are 4 common methods to install pipeline in offshore area: S-Lay, J-Lay, Reel-Lay, and Towed system. Figure 1 below, shows the configuration for each installation method.

.png)

Figure 1 Pipelines Installation Method [1]

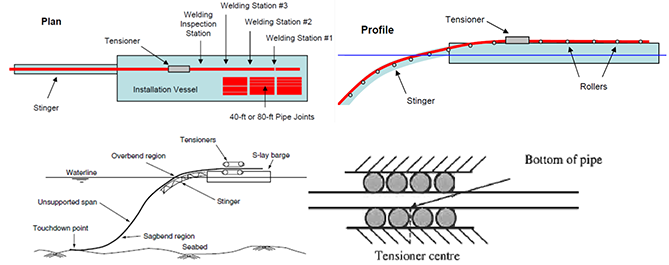

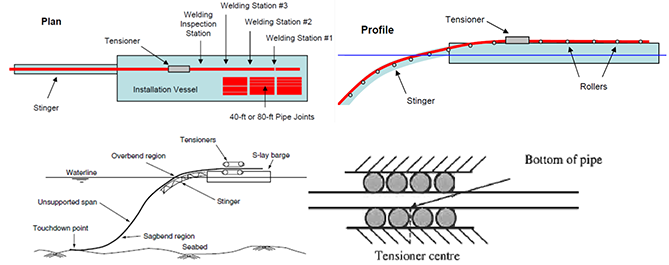

1. S-Lay Method

S-Lay is known as a pipeline installation method that common in shallow water area [2]. The name is taken from its shape configuration during the installation, from stinger to seabed. The vessel positioning of S-Lay method can use dynamic positioning or anchoring. Also, in this method, procedure to connect a typical 12 m or 24 m pipe to other 12 m or 24 m pipe, such as welding, inspection (NDT), and coating, is done on the vessel. The pipe will remain at the stationary, but the vessel is moving. The vessel is allowed to move in this condition because the pipeline its self is supported by rollers and stinger. In addition, pipeline also supported by tensioners to control the sagbend curvature and moment at tensioner because of the pipeline weight [3].

As mentioned before, this method is common in shallow water pipeline installation. However, this method also possible to apply in deepwater area. In consequence, the S-Lay will be very steep and the stinger curvature will increase. These problems can cause plasticity and permanent curvature of the pipe due to steep S-Lay and increase stress and strain in the pipe due to increased curvature of the stinger [4]. Also, this installation method can lay up to 72 inch pipeline outer diameter and the maximum lay rate of this installation method is 5 km/day. The vessel cost of this method is around $350,000/ day. With this amount of lay rate and the cost, this method is consider as relatively cheap method.

As mentioned before, this method is common in shallow water pipeline installation. However, this method also possible to apply in deepwater area. In consequence, the S-Lay will be very steep and the stinger curvature will increase. These problems can cause plasticity and permanent curvature of the pipe due to steep S-Lay and increase stress and strain in the pipe due to increased curvature of the stinger [4]. Also, this installation method can lay up to 72 inch pipeline outer diameter and the maximum lay rate of this installation method is 5 km/day. The vessel cost of this method is around $350,000/ day. With this amount of lay rate and the cost, this method is consider as relatively cheap method.

Figure 2 Detailed Configuration of S-Lay Method [1][2][3]

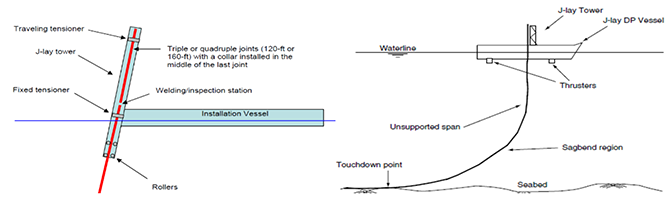

2. J-Lay Method

Similar to S-Lay, this installation method named after pipeline configuration from vessel to seabed. This method require steep angle when pipeline leaves the vessel. Figure 3 shows this method will form a big radius bend and consequently, the stress is not as much as S-Lay. The stinger also not needed in this deepwater installation method. However, the tensioner still needed here to control the weight of the pipe. To maintan the vessel position, dynamic positioning system is used [2].

Figure 3 J-Lay Detail Configuration [buyenguo]

The welding, inspection, and coating is similar to S-Lay, done in vessel as well. The amount of station is not as much as S-Lay method and this result in slower time to lay the pipe. Moreover, this method can install up to 32 inch pipeline, less than S-Lay due to vessel capacity [5]. In addition, the lay rate of this method is up to 2.5 km/day with vessel price $500,000 /day. This method is consider as expensive method.

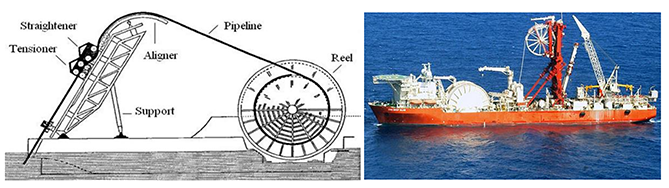

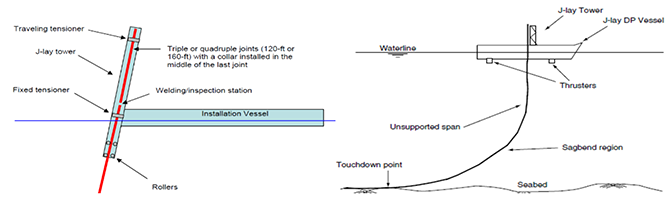

3. Reel-Lay Method

Different with S-Lay and J-Lay, the pipeline in this installation method is fabricated onshore. After fabrication, the pipeline will reeled to drum (or known as carousel). It means that the pipeline is being plastically deform when its reeled. During the installation, this method can follow both of S-Lay or JLay configuration depend on its vessel capability. In this method, the main thing need to be consider is the pipeline plastic strain and deformation. These two items need to be maintained so the value of both thing still below the allowable value.

Figure 4 Reel-Lay Configuration (left: S-Lay, right J-Lay) [2][6]

In this method, the amount of pipe can be laid is limited to the drum capacity. So, the vessel need to back to spool base to take more drum to continue the laying. However, because of that problem, for short distance pipe laying, this method is very efficient. The lay rate of this vessel is up to 20 km/day with vessel cost is $200,000 /day. This method is very cheap. However, the pipeline diameter is limited to 18 inch. The reason it cannot lay higher diameter of pipeline is because with higher pipeline diameter, the wall thickness usually will increase and this result in the plastic deformation. The plastic deformation of high diameter pipeline will surpass the allowable threshold (when reeled to drum) [5].

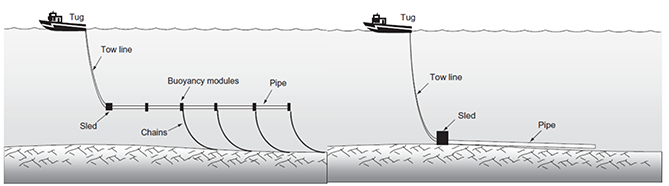

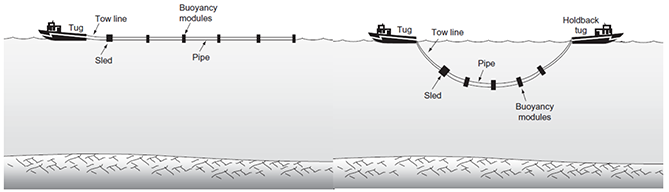

4. Towed System

In this method pipeline is constructed onshore, similar with reel-lay method. This method commonly used for install bundle. In addition, this method also suitable for install pipeline in wide rivers. This methods is divided into three:

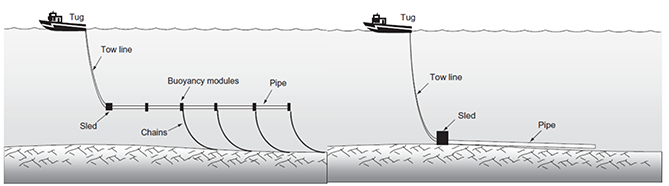

·Bottom Tow

This method is applicable for soft and flat seabed because the pipeline will be pulled through the seabed until it reach the desired location. Also, an additional coating is needed for halfbottom of the pipeline to protect the outer layer of the pipeline (usually corrosion coating or concrete coating layer). This tow method required a sled and put it in front of the pipeline and then connected to vessel by tow line. This sled weight must be higher than the pipeline submerged weight to maintain the initial friction from the soil. [2]. However, this method cannot be use if there is a crossing or want to cross it with other pipeline. Otherwise, there will be need to build protection structure and it will affect the cost efficiency.

·Off Bottom Tow

The procedure of using this method is quite same with bottom tom. However, the difference is this type of tow method is using buoyancy module on the pipe and consequently the pipelines will float above the seabed. The buoyancy module is attached by chain which touch the seabed. The purpose of this method is if this pipelines need to cross other pipeline, just place this pipelines on the concrete mat and no need to build additional protection structure. Other benefit of this method is no additional coating needed because there is no friction between the pipeline and the seabed. This method is very sensitive to relative height from the seabed because the float height of the pipelines need to be higher than any other existing structure and obstacle around the location [2].

Figure 5 Off-Bottom Tow (left) and Bottom Tow (right) [2]

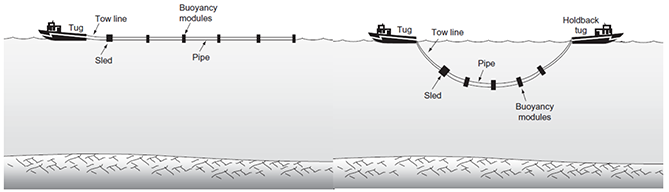

·Mid-depth Tow

This method has similar idea with off bottom tow method. However, in this method high tension is applied for keeping the pipelines at desire position. The tension is given by two vessel at each end of the pipelines. This method usually use another vessel to monitor the pipeline height by using subsea transponder. After that, the signal is sent to the tow vessel to adjust their thruster to maintain the pipelines height. This method is very suitable in an area with many existing facilities [2]

·Surface Tow

This method is similar with mid-depth tow. The difference is this method does not require tow lines to connect the pipelines to vessel. So each end of the pipelines will be connected to the vessel and keep the pipelines on the water surface like showed on figure 6.

Figure 6 Surface Tow (left) and mid-depth tow (right) [2]

This four method is widely used around the world. The method selection is depend on many consideration and circumstances. Table 1 show the summary of pipe laying system comp.

.png)

Author

26003

26003

06 Aug 2021

06 Aug 2021 11049 kali

11049 kali